Kód: 06823856

MINIMUM QUANTITY LUBRICATION GRINDING USING NANOFLUIDS

Autor Bin Shen

Grinding is widely used in the manufacture of §components requiring fine tolerances and smooth §finishes; however, it is recognized as one of the §most environmentally unfriendly manufacturing §processes. Large amount of cutting f ... celý popis

- Jazyk:

Angličtina

Angličtina - Vazba: Brožovaná

- Počet stran: 144

Nakladatelství: VDM Verlag Dr. Müller, 2009

- Více informací o knize

Mohlo by se vám také líbit

-

Subalternity and Difference

5255 Kč -

Mom! I Want to Be a Star

384 Kč -

Huperum

614 Kč -

Fans, Feminisms and 'Quality' Media

1058 Kč -

Technological Communities and Networks

5255 Kč -

Russian-American Dialogue on the American Revolution

2270 Kč -

Russia's Authoritarian Elections

4990 Kč -

Politics of Transition in Central Asia and the Caucasus

1959 Kč -

Introduction to Complexity and Complex Systems

7286 Kč -

Family Interventions in Substance Abuse

5755 Kč -

4D CAD and Visualization in Construction

10348 Kč -

PASSION ON THE VINE

369 Kč -

Plays of W. B. Yeats

1551 Kč -

Integration in Eclipse

1490 Kč

Darujte tuto knihu ještě dnes

- Objednejte knihu a zvolte Zaslat jako dárek.

- Obratem obdržíte darovací poukaz na knihu, který můžete ihned předat obdarovanému.

- Knihu zašleme na adresu obdarovaného, o nic se nestaráte.

Více informací o knize MINIMUM QUANTITY LUBRICATION GRINDING USING NANOFLUIDS

Nákupem získáte 149 bodů

Anotace knihy

Anotace knihy

Grinding is widely used in the manufacture of §components requiring fine tolerances and smooth §finishes; however, it is recognized as one of the §most environmentally unfriendly manufacturing §processes. Large amount of cutting fluids are used §in grinding for a variety of reasons such as §improving wheel life, reducing workpiece thermal §damage and improving surface finish. Government §regulation, environmental protection, public §awareness, and the need for cost reduction have all §promoted the development of new environmentally §conscious grinding processes.§§Therefore, the author proposed Minimum Quantity §Lubrication (MQL) grinding in this book by focusing §on the cutting fluids, grinding wheels, and thermal §management. Nanofluids, a new class of fluids §engineered by dispersing nanometer-size solid §particles in base fluids to increase heat transfer §and tribological properties, were studied as §potential cutting fluids. The insufficient cooling §problem of MQL grinding can be improved by using §vitrified bond CBN wheels. A grinding thermal model §based on the finite difference method has also been §developed to investigate the thermal aspects in the §grinding process. Grinding is widely used in the manufacture of §components requiring fine tolerances and smooth §finishes; however, it is recognized as one of the §most environmentally unfriendly manufacturing §processes. Large amount of cutting fluids are used §in grinding for a variety of reasons such as §improving wheel life, reducing workpiece thermal §damage and improving surface finish. Government §regulation, environmental protection, public §awareness, and the need for cost reduction have all §promoted the development of new environmentally §conscious grinding processes.§Therefore, the author proposed Minimum Quantity §Lubrication (MQL) grinding in this book by focusing §on the cutting fluids, grinding wheels, and thermal §management. Nanofluids, a new class of fluids §engineered by dispersing nanometer-size solid §particles in base fluids to increase heat transfer §and tribological properties, were studied as §potential cutting fluids. The insufficient cooling §problem of MQL grinding can be improved by using §vitrified bond CBN wheels. A grinding thermal model §based on the finite difference method has also been §developed to investigate the thermal aspects in the §grinding process.

Parametry knihy

Parametry knihy

1490 Kč

- Plný název: MINIMUM QUANTITY LUBRICATION GRINDING USING NANOFLUIDS

- Podnázev: Leading to the success of MQL grinding: cutting fluids, grinding wheels, and thermal management

- Autor: Bin Shen

- Jazyk:

Angličtina

Angličtina - Vazba: Brožovaná

- Počet stran: 144

- EAN: 9783639153460

- ID: 06823856

- Nakladatelství: VDM Verlag Dr. Müller

- Hmotnost: 233 g

- Rozměry: 220 × 150 × 8 mm

- Rok vydání: 2009

Oblíbené z jiného soudku

-

Dune

216 Kč -

Haunting Adeline

621 Kč -

Berserk Deluxe Volume 2

1092 Kč -

White Nights

90 Kč -

Powerless

291 Kč -

Atomic Habits

330 Kč -

Dune Messiah

228 Kč -

Berserk Deluxe Volume 3

1142 Kč -

One Day

221 Kč -

Berserk Deluxe Volume 1

1115 Kč -

Iron Flame

368 Kč -

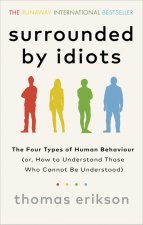

Surrounded by Idiots

213 Kč -

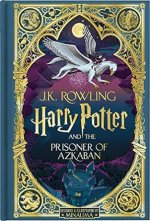

Harry Potter and the Prisoner of Azkaban (Minalima Edition)

993 Kč -

Gravity Falls Journal 3

443 Kč -

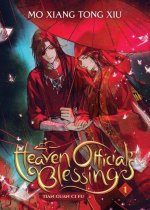

Heaven Official's Blessing: Tian Guan Ci Fu (Novel) Vol. 1

440 Kč -

The Creative Act

568 Kč -

Dune

215 Kč -

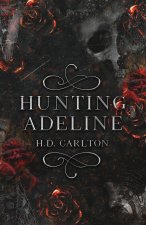

Hunting Adeline

624 Kč -

A Little Life

291 Kč -

Children of Dune

230 Kč -

Heaven Official's Blessing: Tian Guan Ci Fu (Novel) Vol. 2

426 Kč -

Bungo Stray Dogs, Vol. 8 (light novel)

379 Kč -

Percy Jackson and the Olympians 5 Book Paperback Boxed Set

944 Kč -

Solo Leveling, Vol. 1

440 Kč -

The Prisoner's Throne

191 Kč -

Court of Thorns and Roses

268 Kč -

Cry Baby Coloring Book

276 Kč -

Fourth Wing

321 Kč -

Icebreaker

199 Kč -

Berserk Deluxe Volume 6

1089 Kč -

Avatar, the Last Airbender: The Kyoshi Novels (Box Set)

986 Kč -

The 48 Laws of Power

601 Kč -

House of Leaves

462 Kč -

Twisted Lies

213 Kč -

Dune Messiah

214 Kč -

No Longer Human

317 Kč -

48 Laws Of Power

331 Kč -

Twisted Games

213 Kč -

Caraval Paperback Boxed Set

902 Kč -

Solo Leveling, Vol. 2

437 Kč -

Open Circuits

907 Kč -

Berserk Deluxe Volume 5

1119 Kč -

Heaven Official's Blessing: Tian Guan Ci Fu (Novel) Vol. 3

414 Kč -

Berserk Deluxe Volume 4

1292 Kč -

Court of Mist and Fury

206 Kč -

SOLO LEVELING V08

436 Kč -

English File Upper Intermediate Multipack A (4th)

531 Kč -

CHAINSAW MAN V14

251 Kč -

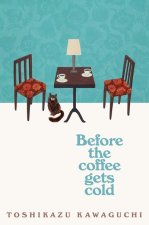

Before the Coffee Gets Cold

184 Kč

Osobní odběr Praha, Brno a 12903 dalších

Copyright ©2008-24 nejlevnejsi-knihy.cz Všechna práva vyhrazenaSoukromíCookies

Vrácení do měsíce

Vrácení do měsíce 571 999 099 (8-15.30h)

571 999 099 (8-15.30h)